The loading dock is essential to any business. It should operate safely, efficiently, and dependably, as it’s a vital part…

Aerosol storage cages play a crucial role in ensuring safety, compliance, and efficient management of potentially hazardous materials. These cans…

Over the past decade, the warehousing and distribution center sector has grown substantially, with a workforce exceeding 1.9 million individuals…

Industry: Environmental business manufacturing & supply laboratory in Greenville, TexasChallenge: Increase storage space, safety, and organization within a new 500,000-square-foot…

If you have employees working at heights, simply providing fall protection equipment is not enough. As an employer, you are…

For the 8th consecutive year, W.W. Cannon, LLC is proud to receive the reputable MHEDA MVP (Most Valuable Partner) Award…

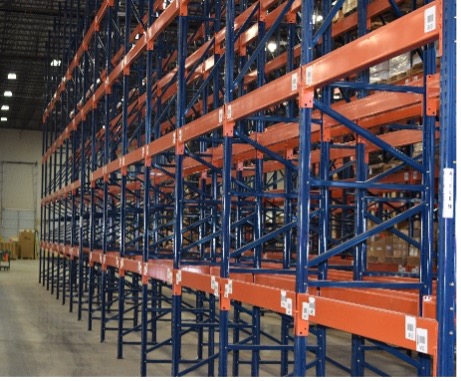

Machinery, Pallet Rack, Shelving all stack up short without a solid barrier to safeguard them. Install a heavy-duty guardrail barrier system…

Machinery, Pallet Rack, Shelving all stack up short without a solid barrier to safeguard them. Install a heavy-duty guardrail barrier system…

Machinery, Pallet Rack, Shelving all stack up short without a solid barrier to safeguard them. Install a heavy-duty guardrail barrier system…

We were able to design and install a cost-effective and high-quality in-plant, pre-engineered office solution with air conditioning and guardrail…

For the 8th consecutive year, W.W. Cannon, LLC is proud to receive the reputable MHEDA MVP (Most Valuable Partner) Award…

Our large manufacturing client needed secured access for their parts, tools and inventory. WireCrafters Style 840 Wire Mesh Partitions was…