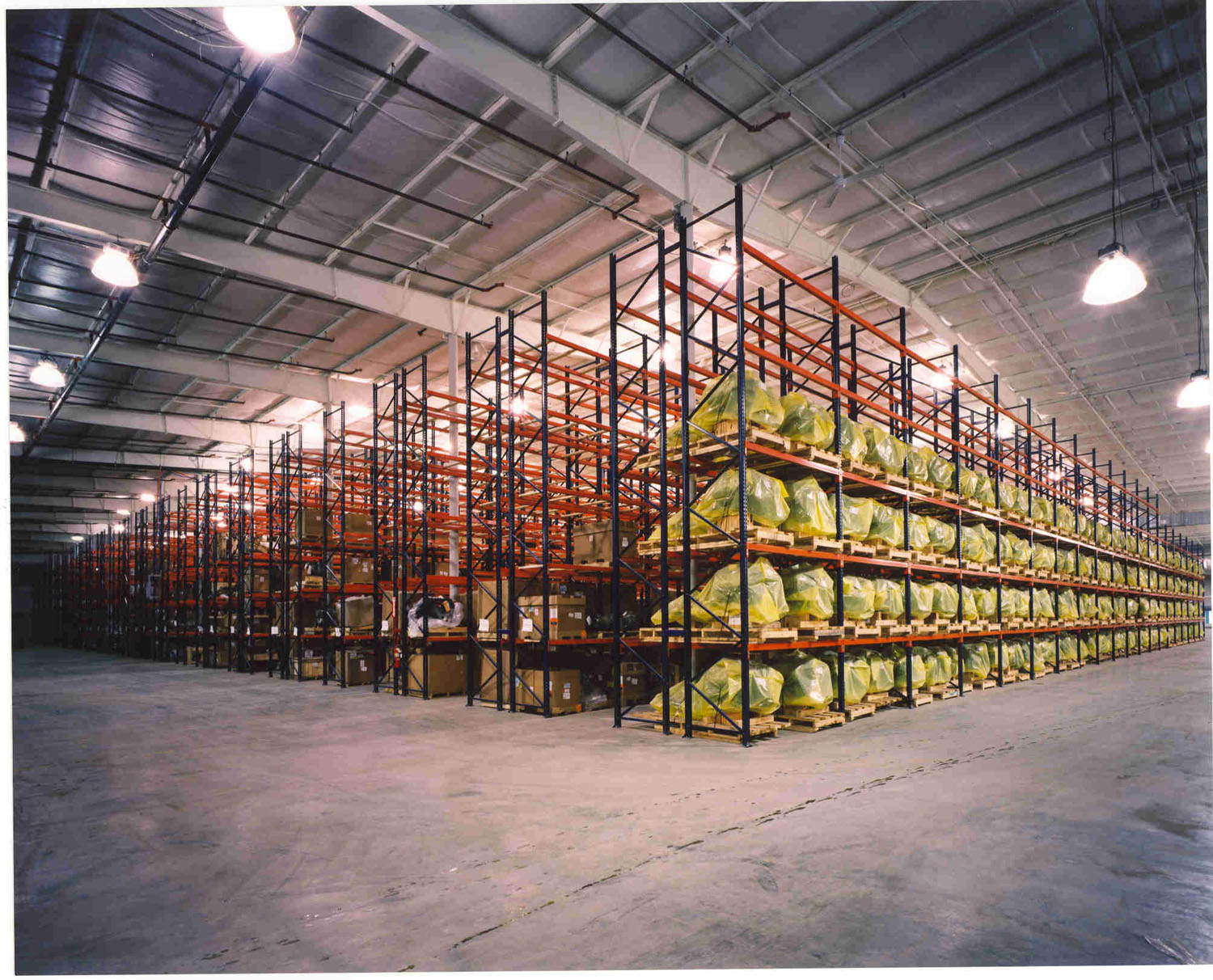

11 Steps to Design Your Warehouse Rack System

Designing a Selective Rack Project – 11 Straight Forward Steps

When consider designing your Selective Rack project it is recommended that a structural engineer evaluate the project. In some areas local codes will require a P. E. Stamp depending on location and application.

The following are design criteria that our structural engineer will need to evaluate your project:

1. Determine Pallet / Load Characteristics

- What are you storing? What are the sizes of your pallets, as well as the weight capacity per shelf?

2. Consider your Handling Equipment Capabilities and Limitations

- How much space is required? How high will the lift go and what is the turning radius required?

3. Consider Storage Area Capabilities and Limitations

- What is your ceiling height, floor construction and what obstructions exist?

4. Determine Beam Length

- Number of loads per section sizes and spacing is required.

5. Determine Beam Capacity

- Number of loads per Beam Level and weight of Pallets.

6. Determine Frame Depth

- This would be the depth of pallet less 6 inches.

7. Determine Upright Frame Height

- This is determined by number of loads high (including pallet) plus 4” for clearance. Your forklift equipment height capability needs to exceed height of Upright.

8. Select Upright Frame Capacity

- First information needed will be exact location of project so engineer can evaluate seismic requirements.

- Capacity is determined by weights of loads per section multiplied by the number of Beam Levels, considering the Beam Spacing.

9. Determine Aisle Width

- Determine turning radius of lift truck plus 12”.

10. Determine Row Spacers and Wall Ties

- If possible flue spaces of 3” – 6” is recommended to allow changing of Beam Levels.

11. Total Quantities Required

- Beams – Number of Beams X Number of Bays per Row X Number of Rows.

- Frames – Number of Bays per Row, plus One X Number of Rows.

- Wall Ties – Number of Rows against wall, plus 1 X Number of Wall Ties per frame.

- Row Spacers – Number of Back to Back Double Rows, plus 1 X the Number of Row Spacers per Frame Line.

To save you time while you are considering your rack project, contact W.W. Cannon, Inc. at 800.442.3061. We will provide consultation for your design, layout, build and installation according to your unique requirements.

Find the Right Solution

How can we help you solve your challenges? Reach out and someone will be in touch soon for more details.

Other Topics

Related Stories

The loading dock is essential to any business. It should operate safely, efficiently, and dependably, as it’s a vital part…

Aerosol storage cages play a crucial role in ensuring safety, compliance, and efficient management of potentially hazardous materials. These cans…

Over the past decade, the warehousing and distribution center sector has grown substantially, with a workforce exceeding 1.9 million individuals…