We are proud to be a certified Starrco Modular Office distributor. Starrco is the preferred source for modular building systems…

Being a Texas company, we KNOW how to keep cool. Our experienced specialists solve heat issues with a variety of…

As a company grows, storage and accessibility can become an issue. Pallet Flow Rack can double your storage space the…

WireCrafter’s portable employee separation panels help to enforce social distancing safety parameters defined by the CDC for the workplace. These portable…

Our client renovated the historic Sinclair building in Fort Worth TX into a luxury hotel. We installed a freight elevator…

We can help you efficiently and quickly turn your open areas into enclosed, safe workspaces with Starrco’s office wall panel…

Patient Screening Booths make No-Touch Testing possible. Currently, the safest and most efficient way to apply COVID-19 swab tests, completely…

During this challenging time, W.W. Cannon is keeping its doors OPEN for dock and door repair servicing and warehouse equipment…

We are very excited to officially announce the launch of our newly designed website. As an industry leader providing turnkey…

After a hard working season, your dock doors, dock levelers, and loading dock equipment are more than ready to be…

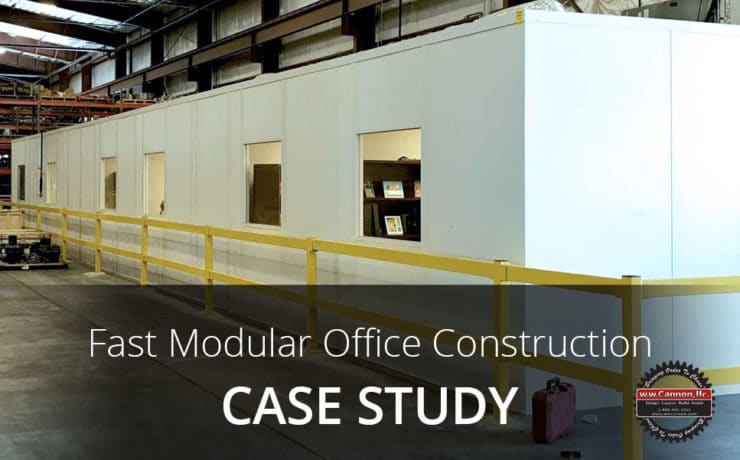

Our manufacturing client in DeSoto TX acquired a new warehouse to expand their operations. They needed a QC office with…

Our client moved into the perfect location – but had no office space. We installed an in-plant modular office system…